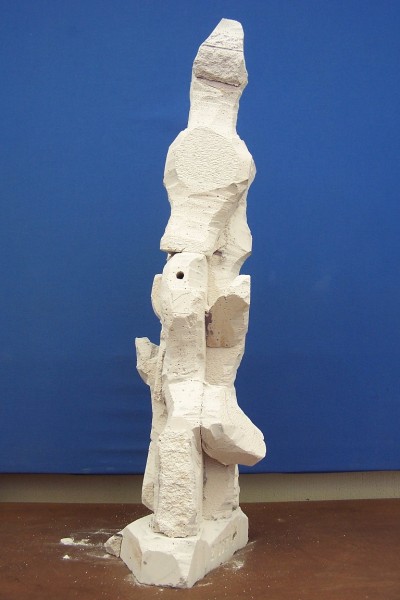

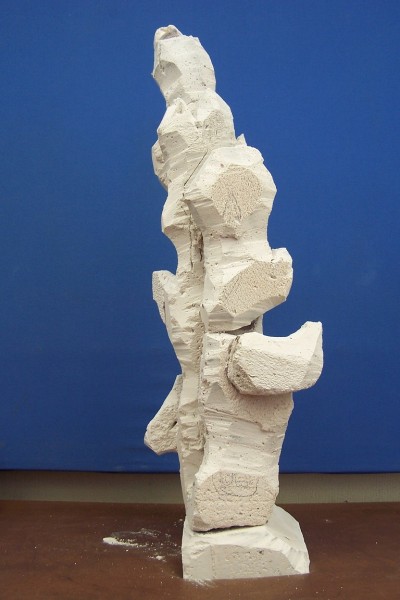

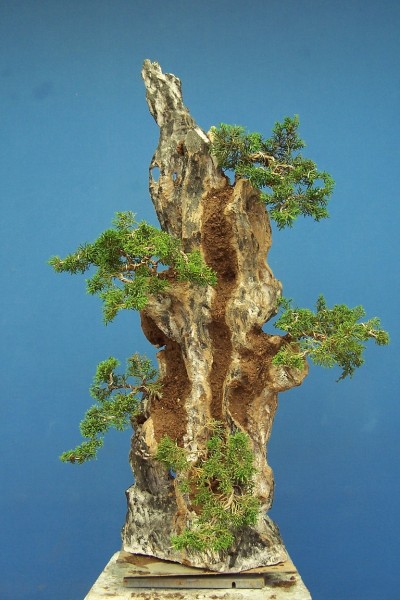

This rock has only recently been completed using hebel panel offcuts which are basically light weight autoclaved concrete . This rock will be freestanding in a tray not a potted rock planting so i have used a muck to help retain moisture and also aid in the growth of the moss being used . The moss will serve 2 purposes by which it will keep the rock cooler and also represent the waterfall which has been carved into the rock as a minor feature . I have used a thick layer of muck both inside the hollowed section for the plants and also along the crevices carved into the rock itself .  I have pre-wired the plants to prevent to much movement once they are positioned into each pocket .With all the Junipers in the desired position

I have pre-wired the plants to prevent to much movement once they are positioned into each pocket .With all the Junipers in the desired position i then set about applying various types of moss and lychen .

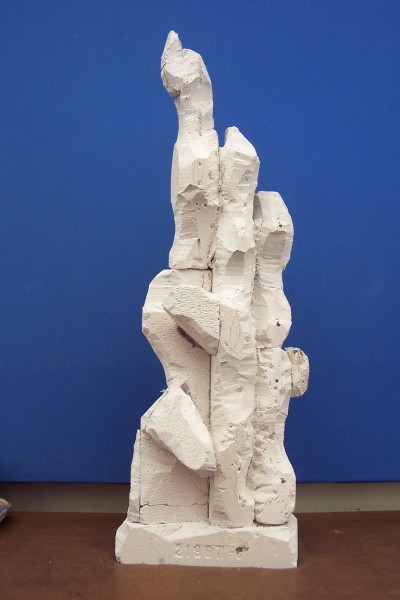

i then set about applying various types of moss and lychen .  This over time releases spores and the older moss can be removed and a closer new mat of moss will begin to grow and adhere to the surface for a more realistic look .

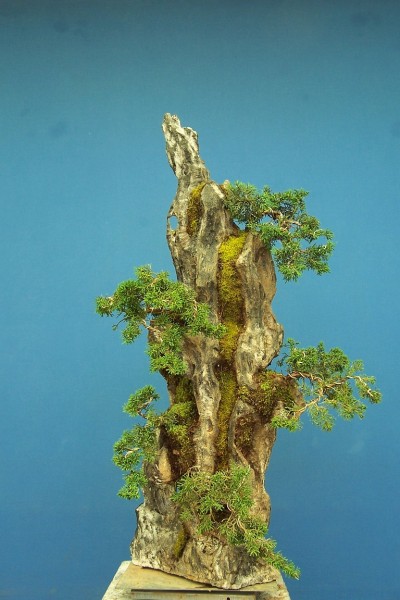

This over time releases spores and the older moss can be removed and a closer new mat of moss will begin to grow and adhere to the surface for a more realistic look . With the mosses finished i then give the Junipers a slight trim and manipulate the trunk lines to a more pleasing position .

With the mosses finished i then give the Junipers a slight trim and manipulate the trunk lines to a more pleasing position . With all the work done it gets a good wash

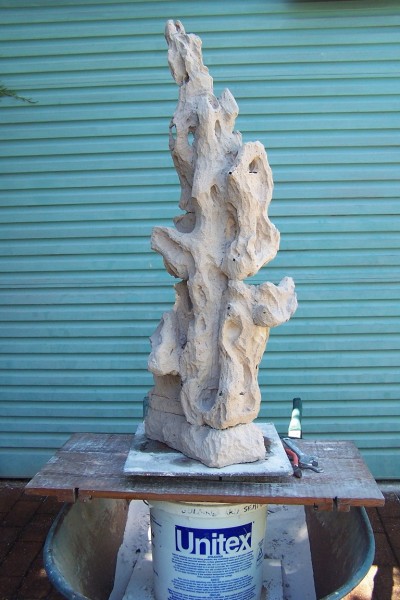

With all the work done it gets a good wash and under the pergola it goes to allow the tree’s to settle and the moss to flourish

and under the pergola it goes to allow the tree’s to settle and the moss to flourish  . This will eventually be placed in a shaded area

. This will eventually be placed in a shaded area  behind the house out of the wind and radiant heat

behind the house out of the wind and radiant heat which is a major problem here over the Summer months

which is a major problem here over the Summer months . Cheers Alpineart

. Cheers Alpineart